Phoenix Technologies and German Edge Cloud Partner to Launch On-Prem AI Factory for Physical AI in Manufacturing

Phoenix Technologies AG and German Edge Cloud (GEC) today announced a strategic partnership to deliver a revolutionary, on-premises AI Factory solution designed to accelerate industrial automation through physical AI, all while maintaining full data sovereignty, security, and operational speed.

At a time when industrial enterprises are under immense pressure to digitalize and modernize with AI while complying with increasingly strict data security and regulatory frameworks, this partnership provides a uniquely sovereign, modular, and production-ready alternative. The AI Factory, based on Phoenix Technologies’ Armored AI Factory architecture and deployed using GEC’s ONCITE Digital Production System (DPS), offers manufacturers a turnkey, air-gapped solution for deploying high-performance AI directly into factory environments—without relying on public cloud infrastructure.

The core of this physical AI initiative is built around the speedboat paradigm: fast, self-contained, and mission-driven AI deployments that avoid the inertia of centralized IT modernization projects. By delivering a fully managed stack—spanning design, hardware procurement, installation, configuration, and operational training—Phoenix ensures each AI Factory is production-ready from day one. The platform includes a confidential computing foundation that safeguards all conversational, vector, and inference data, while also supporting advanced capabilities like Retrieval-Augmented Generation (RAG), agentic AI, and private LLMs with browser-local memory.

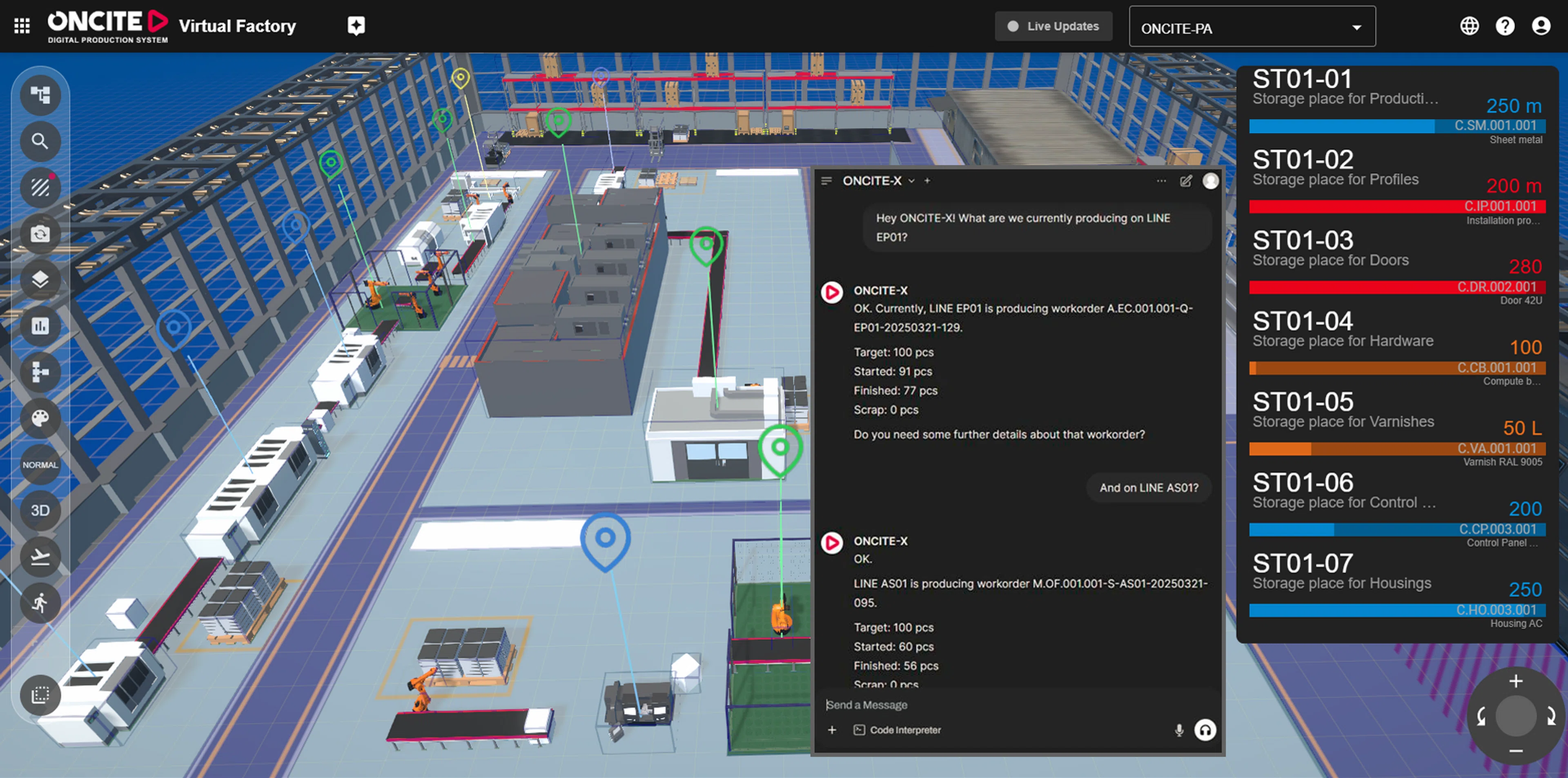

German Edge Cloud complements this platform by integrating automation solutions directly into robotic workflows at production sites. Leveraging its ONCITE DPS—proven in high-compliance industrial environments—GEC simplifies the deployment of AI-driven manufacturing intelligence through pre-configured software modules delivered on physical data carriers. This approach dramatically reduces complexity, eliminates cloud dependencies, and enables full control over operational data. Only customer-specific parameters such as IP addresses and certificates are added on site, ensuring rapid deployment and a short time to value.

This Physical AI deployment model empowers factory operators to sense, analyze, and act in real time within the constraints of highly secure, mission-critical environments. Whether enabling intelligent robotic operations, optimizing energy consumption, or delivering granular track-and-trace transparency, the system functions entirely within an isolated network—meeting the highest standards for data protection and process integrity.

Importantly, the full solution is available through an OPEX commercial model, allowing manufacturers to scale their AI capabilities without incurring heavy upfront capital costs. The modular, containerized design of the AI Factory also supports horizontal scaling across production lines or geographic locations, while maintaining operational autonomy at each site.

This joint solution is strategically poised to attract a wave of new industrial customers across Europe’s highly regulated manufacturing sectors. By offering an on-prem, sovereign AI deployment model that bypasses the cloud while meeting GDPR and EU AI Act requirements, the Phoenix-GEC AI Factory unlocks adoption among traditionally cautious manufactureres – especially those in production-critical operations - who have previously delayed AI initiatives due to regulatory and operational constraints.

In parallel, the system augments or replaces overburdened and under-resourced local IT teams by providing a full-stack, production-ready AI infrastructure. With built-in deployment, configuration, and maintenance services, it reduces dependence on in-house specialists—allowing industrial organizations to reallocate technical talent toward higher-value innovation and operational roles. The modular nature of the AI Factory ensures that IT teams can scale rapidly without incremental hiring or retraining cycles, further supporting lean operations.

Most critically, this partnership addresses a significant unmet need among GEC’s existing industrial client base: the demand for physical AI capable of acting autonomously within isolated, mission-critical environments. Until now, manufacturers have lacked AI solutions that combine real-time responsiveness, full data sovereignty, and deterministic operational control—without compromising security or increasing system complexity. This AI Factory fills that void, empowering clients to activate latent AI use cases in energy optimization, real-time defect detection, predictive maintenance, and intelligent robotics with unprecedented speed and compliance assurance.